Combustion test facilities, which it utilizes to achieve even more sophisticated combustion technologies that form the basis of boiler performance, including lower nitrogen oxide (NOx) emissions, less unburnt fuel, and a reduced excess air ratio. We are particularly focused on enhancing the following two functions of our combustion test facilities to support cutting-edge technological development.

With the introduction of new and improved combustion test instruments, many technicians are asking what the real difference is between measuring oxygen and measuring carbon dioxide. Is one method better than the other? Is the end result the same?

To answer these questions, we will present a simple comparison, and will discuss the differences and similarities that exist.

First, combustion is the result of chemical reactions. We combine AIR comprised of approximately 21% OXYGEN and 79% NITROGEN with FUEL OIL, which is approximately 85% CARBON and 15% HYDROGEN. A perfect oil burning system, then, would combine the AIR and OIL in the exact amounts to result in a perfect combustion level known as the ultimate carbon dioxide level, or stoichio-metric ratio. This merely means that the amount of hydrogen and carbon in the oil is mixed precisely with the oxygen. It is chemically correct with no “leftovers”.

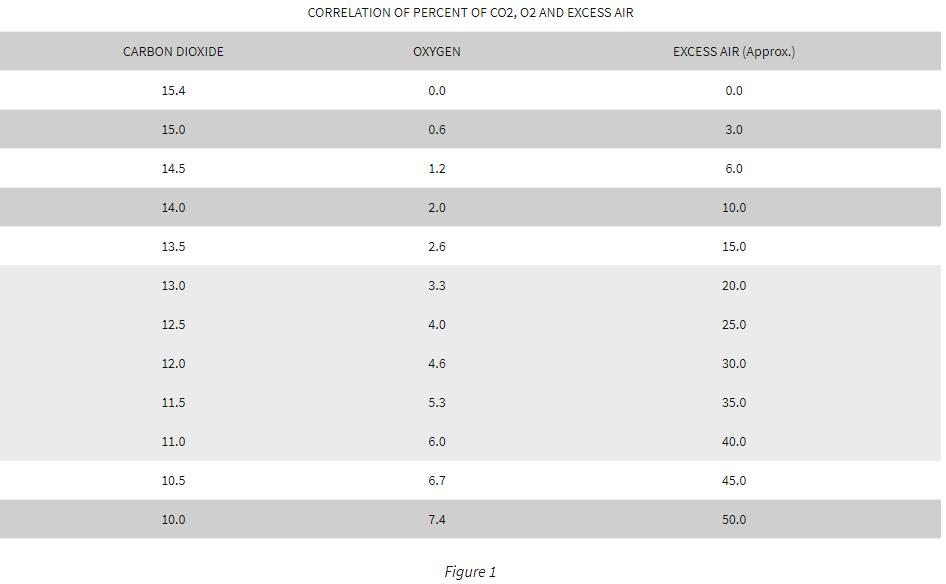

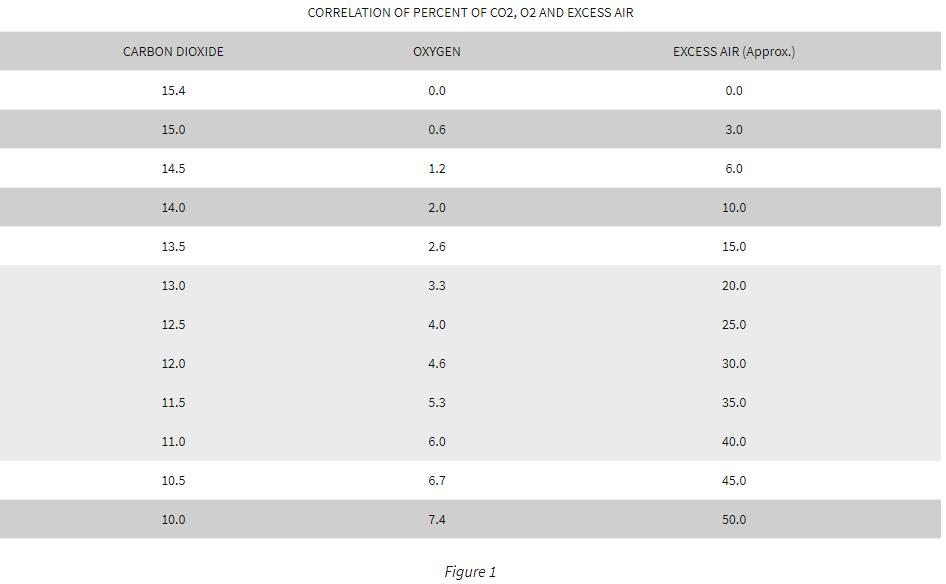

Under these controlled conditions, the CARBON DIOXIDE (CO2) analysis would reveal the highest possible reading. (See Figure 1.) What would the equivalent oxygen (O2) level read? You are right if you said zero percent. Again, see Figure 1. Why? Because zero percent excess air laden with oxygen is present in the flue gas with perfect combustion.

Now, perfect combustion sounds good, but it usually is not practical in reality. Generally, we see somewhat lower CO2 or higher O2 levels in the field. This is determined by both the equipment design and the level at which smoke generation

occurs. It is recommended practice to obtain a TRACE of smoke at steady-state operation, then measure the CO2 or O2 and increase the burner air setting in order to lower the CO2 by 1% or raise the O2 by 1% at a zero smoke level.

When we take this action, we are actually increasing the excess air, which can be thought of as reserve or insurance air. Now a margin of protection is built in to accommodate variables during the heating season. This should keep system sooting to a minimum.

The excess or reserve air affects the volume of flue gas by increasing it proportionately. Figure 1 shows the effect this has on the percentages of OXYGEN and CARBON DIOXIDE.

Remember, as the excess air is reduced, the percent of extra oxygen decreases but the percent of carbon dioxide increases. By increasing the excess air, we lower the carbon dioxide percent, but raise the oxygen. This is kind of a see-saw effect. Actually, you usually set the combustion level for 11-13% CO2 or 3-6% O2 using the guidelines outlined above. This area has been highlighted in Figure 1.

It is very important to use combustion test instruments to determine the most practical level of burner operation. Whether CO2 or O2 is measured, the end results will be identical.