Combustible gas alarms are detectors that respond to single or multiple combustible gas concentrations.

There are two types of combustible gas alarms that are commonly used in daily life: catalytic type combustible gas alarms and semiconductor type combustible gas alarms.

Restaurants, guesthouses, household manufacturing rooms and other places that use gas, natural gas, and liquefied petroleum gas mainly use semiconductor-type combustible gas alarms;

Catalytic combustible gas alarms are mainly used in industrial places where combustible gases and vapors are released.

The catalytic combustible gas alarm uses the resistance change of the refractory metal platinum wire to measure the combustible gas concentration.

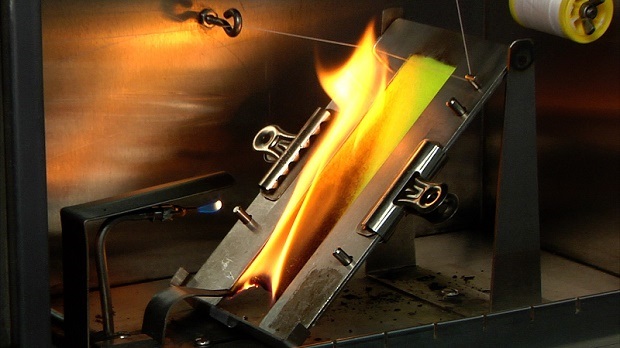

When the combustible gas enters the detector, it causes an oxidation reaction (flameless combustion) on the surface of the platinum wire, and the heat generated increases the temperature of the platinum wire;

The resistivity of platinum wire will change, so when encountering elements such as high temperature, the temperature of platinum wire will change, and the resistivity of platinum wire will change, and the exploration data will also change.

The semiconductor-type combustible gas alarm uses the change of the resistance of the semiconductor surface to measure the concentration of combustible gas.

The principle of the detection part of the combustible gas alarm is that the sensor of the instrument selects the detection element, the fixed resistance and the zero adjustment potentiometer to form a detection bridge.

The bridge uses platinum wire as the carrier catalytic element. After electrification, the temperature of the platinum wire rises to the working temperature, and the air reaches the surface of the element by natural dispersion or other methods.

When there is no flammable gas in the air, the bridge output is zero, and when the air contains flammable gas and disperses to the detection element;

Because the catalysis produces flameless combustion, the temperature of the detection element rises, the resistance of the platinum wire increases, and the bridge loses balance;

As a result, a voltage signal is output, and the magnitude of this voltage is proportional to the concentration of combustible gas;

The signal is amplified, converted from analog to digital, and displayed on the liquid display to show the concentration of combustible gas.

The principle of the detection part is that when the measured flammable gas concentration exceeds the limit value, the enlarged bridge output voltage and the circuit detection set voltage;

Through the voltage comparator, the square wave generator outputs a set of square wave signals to control the sound, the light detection circuit, the buzzer produces a series of sounds, and the light-emitting diode flashes to announce the detection signal.

From the principle of combustible gas alarm, it can be seen that if there is electromagnetic interference, it will affect the signal of exploration, and there will be data error;

If there is a collision or vibration that causes the device to break the circuit, the detection will fail;

If the environment is too humid or the equipment enters water, it may also cause a short circuit in the combustible gas alarm, or a change in the line resistance value, resulting in a detection failure.